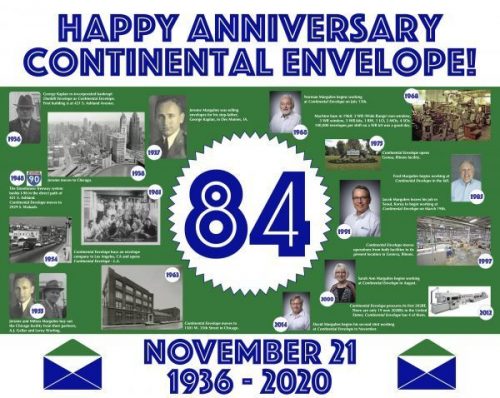

Continental Envelope Celebrates 84 Years!

November 19, 2020

Continental Envelope Wins Bronze Award in 2024 FTA Excellence in Flexography Awards

May 30, 2024

Printing inks are evolving – and taking the printing world with them. Beyond the equipment advancements of the last decade, the new or improved technologies within materials, inks, and solvents have mirrored heightened necessity and drive for ethical practice.

Sustainability Reigns

Sustainability matters to consumers, and the printing industry is no exception. A transition to sustainable practices is predicted to be one of the most influential driving forces for the next five years, based on the work already being done to reduce the environmental impact of printing. Notably, a reduction in volatile organic compounds, or VOC’s, aid in reducing greenhouse gases.

A key development within ink production are two sustainability-friendly options: vegetable-based and water-based printing inks. Environmentally-friendly, vegetable-based inks are commonly composed of oils like soy, linseed, canola, or safflower, and carry many advantages over petroleum-based inks. Water-based inks are primarily water and pigment. While drying times for both of these ink types are longer than other inks (i.e. petroleum or solvent-based), vegetable or water-based inks drastically reduce the amount of VOCs, releasing approximately 2-4% VOC emissions for vegetable-based ink, and even better, <1% for water-based inks.

Improving ink processes has a positive trickle down effect on washing processes, too. When presses operating with petroleum inks are washed, additional VOCs are released – furthering their negative impact. Presses operating with vegetable inks not only release fewer VOCs, but they can be fully cleaned with less water and fewer solvents.

Sustainability in printing is advancing by leaps and bounds, matching consumer values and ensuring a brighter future for the industry as a whole.

Learn more about Sustainability at Continental Envelope.