Our Heritage, Our Promise

Family-owned since 1936, we have delivered the envelopes our customers need, when they need them, for a competitive price.

1930’s & 1940’s

Our Beginning

In the middle of the 1930’s Depression, Continental Envelope was established in Chicago with envelope equipment from its parent company, Minnesota Envelope. From this humble beginning Continental Envelope grew to be one of the leading independent manufacturers of envelopes in the United States. In 1948, it relocated to 2929 South Wabash in Chicago where it remained until 1964. Jerome Margulies led the company from its creation in 1936.

Jerome Margulies, First President of Continental Envelope

Chicago circa 1940

Milton Margulies, Jerome’s brother and partner and George Kaplan from Minnesota Envelope

1950’s & 1960’s

Post-war Growth

This was a period of growth for Continental Envelope. Acquisition of new equipment led to increased machine speeds and market share. In 1964, Continental Envelope moved to 1301 West 35th Street, just west of Comiskey Park. This move enabled further expansion and allowed Continental Envelope the space to continue to acquire the newest equipment, a policy which has been followed to this day. In 1968, Norman Margulies joined the company, providing innovative leadership from a younger generation of the Margulies family.

Sales and office staff, 1961

First shift at the Wabash Avenue plant, 1961

New location on West 35th Street, one mile west of Comiskey Park, 1964

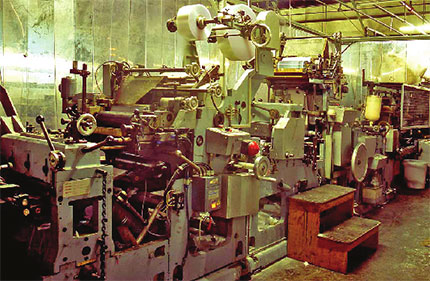

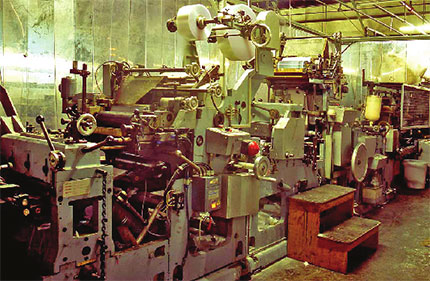

Envelope machine circa 1965

1970’s & 1980’s

Computerization and Modernization

In 1970, Continental Envelope computerized its costing system to help better estimate the manufacturing of envelopes. This began a fifty-year process of improvement has led to our rapid response quote system that continues to satisfy the needs of our customers. During this period, additional machines were brought in to produce the finest quality envelopes at new speeds of 200,000 envelopes per shift. In 1985, Fred Margulies joined the company. His vision led to the move to Geneva, Illinois.

Machinery of the era

Jerome and salesmen circa 1973

Christmas party 1973

Christmas party 1973

1990’s & 2000’s

Our New Building, A Fresh Start

Jacob Margulies, representing the fourth generation of leadership, joined the company in 1993. This was a period of movement for Continental Envelope. In 1997, Continental Envelope built a state-of-the-art facility in Geneva, Illinois. This facility incorporated the best practices in environmental accountability. Waste-water treatment and an advanced pneumatic recycling system were included in the new facility. This was part of the new effort aimed towards ecological stewardship. New, high-speed equipment was added in 2001.

Our new home, Geneva, 1997

Pre-press department making flexo plates

Setting up a press

Our lithographic press

Our RA web

Our RA web

2010’s & 2020’s

Upgrading to High-Speed Equipment

This was a period of growth and upgrading of equipment. With the success of the first high speed press, it became evident that this was the direction that Continental Envelope had to pursue. From 2001 until now, over $20,000,000 of new equipment has been added to enable higher speeds and greater quality in envelope production.

Our new 202 up and running

Our climate controlled warehousing

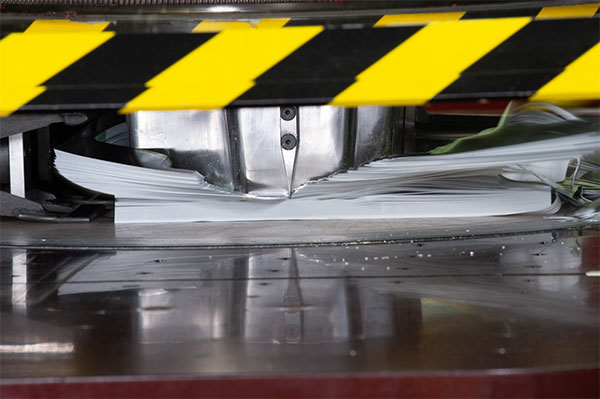

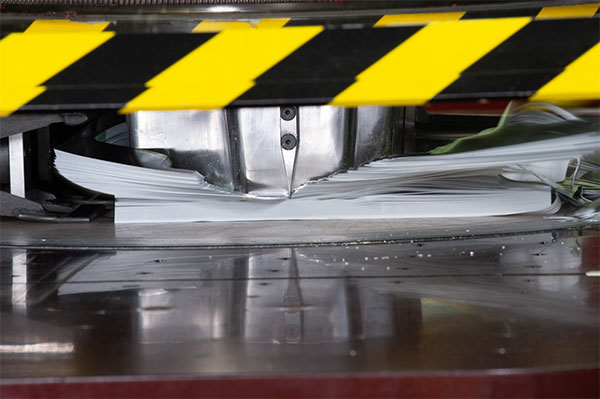

Precision cutting

Ink mixing

Our Heritage, Our Promise

Family-owned since 1936, we have delivered the envelopes our customers need, when they need them, for a competitive price.

1930’s & 1940’s

Our Beginning

In the middle of the 1930’s Depression, Continental Envelope was established in Chicago with envelope equipment from its parent company, Minnesota Envelope. From this humble beginning Continental Envelope grew to be one of the leading independent manufacturers of envelopes in the United States. In 1948, it relocated to 2929 South Wabash in Chicago where it remained until 1964. Jerome Margulies led the company from its creation in 1936.

Jerome Margulies, First President of Continental Envelope

Chicago circa 1940

Milton Margulies, Jerome’s brother and partner and George Kaplan from Minnesota Envelope

1950’s & 1960’s

Post-war Growth

This was a period of growth for Continental Envelope. Acquisition of new equipment led to increased machine speeds and market share. In 1964, Continental Envelope moved to 1301 West 35th Street, just west of Comiskey Park. This move enabled further expansion and allowed Continental Envelope the space to continue to acquire the newest equipment, a policy which has been followed to this day. In 1968, Norman Margulies joined the company, providing innovative leadership from a younger generation of the Margulies family.

Sales and office staff, 1961

First shift at the Wabash Avenue plant, 1961

New location on West 35th Street, one mile west of Comiskey Park, 1964

Envelope machine circa 1965

1970’s & 1980’s

Computerization and Modernization

In 1970, Continental Envelope computerized its costing system to help better estimate the manufacturing of envelopes. This began a fifty-year process of improvement has led to our rapid response quote system that continues to satisfy the needs of our customers. During this period, additional machines were brought in to produce the finest quality envelopes at new speeds of 200,000 envelopes per shift. In 1985, Fred Margulies joined the company. His vision led to the move to Geneva, Illinois.

Machinery of the era

Jerome and salesmen circa 1973

Christmas party 1973

Christmas party 1973

1990’s & 2000’s

Our New Building, A Fresh Start

Jacob Margulies, representing the fourth generation of leadership, joined the company in 1993. This was a period of movement for Continental Envelope. In 1997, Continental Envelope built a state-of-the-art facility in Geneva, Illinois. This facility incorporated the best practices in environmental accountability. Waste-water treatment and an advanced pneumatic recycling system were included in the new facility. This was part of the new effort aimed towards ecological stewardship. New, high-speed equipment was added in 2001.

Our new home, Geneva, 1997

Pre-press department making flexo plates

Setting up a press

Our lithographic press

Our RA web

Our RA web

2010’s & 2020’s

Upgrading to High-Speed Equipment

This was a period of growth and upgrading of equipment. With the success of the first high speed press, it became evident that this was the direction that Continental Envelope had to pursue. From 2001 until now, over $20,000,000 of new equipment has been added to enable higher speeds and greater quality in envelope production.

Our new 202 up and running

Our climate controlled warehousing

Precision cutting

Ink mixing

Mission

Envelopes are what we do.

Service is who we are.

We can help you:

- Manage your expenses

- Improve speed to market

- Better communicate your message

Our new technologies serve your goals:

- Faster response times

- Greater flexibility

- Excellent print quality