We deliver quality.

On-time, every time.

At Continental Envelope, we’re dedicated to investing in the best new equipment and technology to produce the highest quality envelopes. Our strategic focus on great equipment – and great equipment operators – results in quicker response times, more flexibility and consistently outstanding product quality.

Capabilites

High Speed Web

- 12 million envelopes per day with 7 web presses

-

Supports 5-color enhanced flexo printing, including full 4-color process

-

Spot-registered in-line embossing for precision branding

-

Offers in-line soft-touch coatings, spot/overall varnish, and custom PMS UV inks for high-impact finishes

-

Capability to convert pre-printed rolls

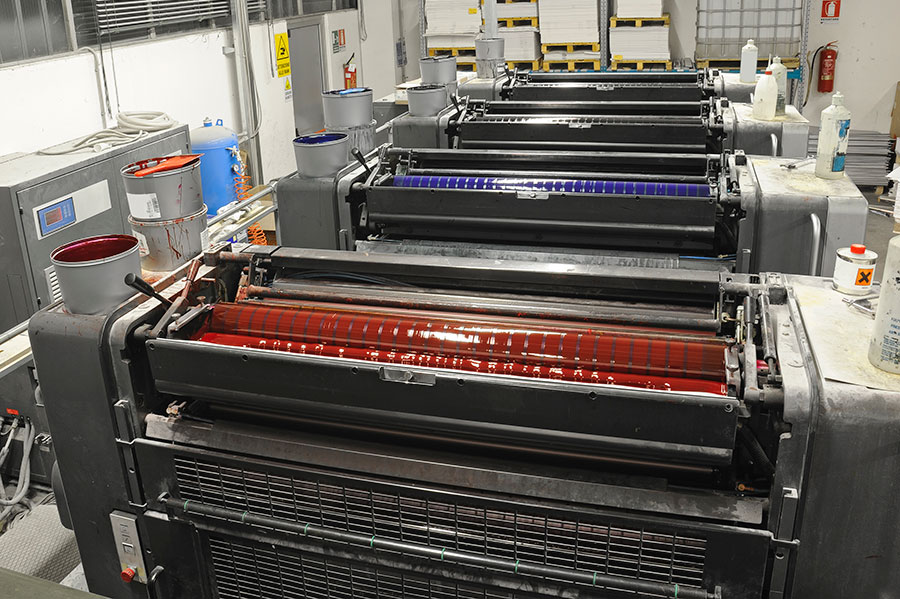

Enhanced Flexo

-

Prints with five spot colors and four-color process for complex branding and campaign work

-

Features anilox rollers that optimize ink transfer and reduce setup time

-

Capable of printing on coated (150 LPI) and uncoated (133 LPI) stocks

-

Integrates double-chambered doctor blades for enhanced ink control and web consistency, which is ideal for campaigns requiring tight registration and speed

Quality Litho Options

- Achieve rich, full-spectrum visuals with litho print options which features a 4-8 color range. Litho print options include:

- Flat sheet and roll-to-roll

- In-line roll to sheet capability

- Variable sheet sizes for a perfect layout every time

- Dramatic cost savings over trimmed 4-sided sheets

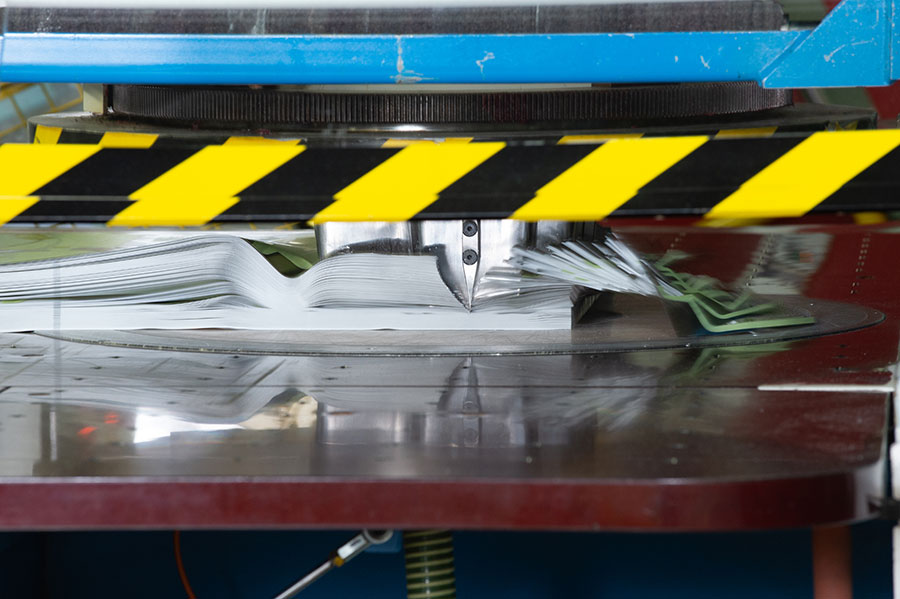

Computerized Die-Cut + Folding

- 3 high-speed, die-cutting presses capable of producing up to 6 million envelope blanks per day on plain or pre-printed stock

- 4 high-speed folding machines capable of converting die-cut envelopes

- Enables production of non-standard sizes, shapes, and window configurations with consistent quality

Storage: Gravity Racking System

- Store your product in a humidity and temperature controlled environment with over 500 pallet positions

- Provides volume ordering and storage capabilities

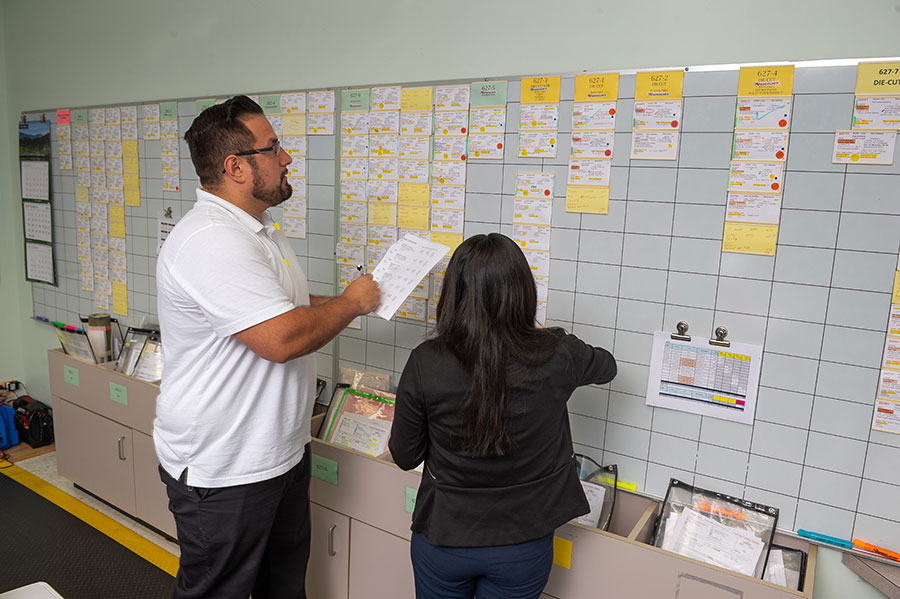

Customer Service in a Class by Itself

Our best-in-class equipment combined with unparalleled customer service keeps our customers very happy. Our seasoned team keeps a watchful eye on every detail of every job. We manage the entire process – from our proprietary quoting system, to taking raw materials and creating a high-quality finished product that meets your highest expectations. We make sure your job is done right the first time. No surprises, no excuses.

Our plant is our investment in your success!

We invest strategically in our future competitiveness and your continued satisfaction. Recent investments include ultra-high-speed, four-color process folding machines as well as advanced cutting equipment. If you’d like more specific information about our technology and systems, please call us or send an email to info@continentalenvelope.com